Servo Hydraulic Testing Machine for Fracture Toughness Testing with

High Precision Data Measurement and Control System

Summary:

1. Main Machine Structure

The load frame of the Fracture Toughness Tester (Hydraulic

Universal Testing Machine, UTM) consists of two columns, two guide

rails, and an integrated hydraulic cylinder. The tension testing

space is located at the upper section of the main machine, while

the compression and bending testing spaces are positioned between

the lower crosshead and the worktable—ensuring rational space

allocation for diverse test scenarios.

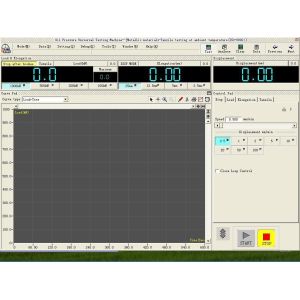

2. Data Measurement & Control System

Equipped with a high-precision A/D converter module, the system

performs real-time acquisition of force, displacement, and

deformation data. It boasts exceptional measurement accuracy and

reliable operational performance, fully complying with GB, ISO,

ASTM, and other international/national standards for tensile,

compression, bending, and shear tests of metal materials.

3. Transmission System

The lower crosshead is driven by a motor via a reducer, chain

transmission mechanism, and lead screw assembly—enabling precise

and smooth position adjustment of the testing space. This design

ensures stable load transmission and accurate control of test

processes, adapting to the size requirements of different test

samples.

Standards:

ISO 6934 BS4449, ASTM C39, ASTM A370, ASTM E4, ASTM E8, ASTME9, ASTMA615, ISO6892, ISO7438, ISO7500-1, ISO 15630 EN10002-4,

GB/T228-2002, GB 16491-2008, HGT3844-2008 QBT 11130-1991, HGT 3849-

2008,GB6349-1986, ASTM C165, EN826, EN1606, EN1607, EN12430 etc.

Principle:

Hydraulic oil stored in the oil tank is delivered into the

hydraulic circuit by a motor-driven high-pressure pump. It

subsequently passes through the high-pressure filter, differential

valve group, and servo valve before entering the hydraulic

cylinder.

The computer transmits precise control signals to the servo valve,

regulating its opening degree and flow direction. This controls the

oil flow rate entering the hydraulic cylinder, thereby realizing

accurate control of test modes such as constant test force rate and

constant displacement rate.

Main technical parameters:

Model | WAW-300D |

Max. test force(kN) | 300KN |

Structure | Two columns two ball screws, oil cylinder down-setting type |

Load range | 2%-100% |

Middle Beam elevating speed (mm/min) | 170 mm/min |

Max. Tensile space (mm) | 700mm |

Max. Compression space (mm) | 600mm |

Piston stroke(mm) | 250mm |

Stranded wire clamping range | Φ6-30mm |

| Flat sample clamping range | 0-15mm |

Power total | 2.2KW |

Compression plate size | Φ120mm |

Bending support roller distance | 300mm |

Packing and Shipping:

Frequently Asked Questions:

Q1: Is your company a trading firm or a manufacturing factory?

A1: We are a factory-integrated trading company—with 18 years of

dedicated expertise in the testing instrument industry and 14 years

of international export experience. We integrate in-house

manufacturing capabilities with global trade services to deliver

end-to-end product and service solutions.

Q2: How can I select the most suitable product?

A2: Our professional technical team will provide optimal tailored

recommendations once you share your specific test requirements

(e.g., test type, material to be tested) and technical

specifications. We base suggestions on your actual application

scenarios to ensure the product fully matches your needs.

Q3: What are your delivery terms?

A3: In most cases, we maintain inventory of standard models for

immediate shipment. For non-stock items, the standard lead time is

15–20 working days upon receipt of the advance payment. If you have

urgent demands, we can arrange priority production to shorten the

delivery cycle as much as possible.

Q4: Do you offer customization services?

A4: Yes, we provide comprehensive customization services. In

addition to standard testing machines, we can develop customized

solutions tailored to your specific requirements—such as modified

technical parameters, specialized fixtures, or custom software

functions. Please feel free to share your detailed needs, and our

R&D and engineering teams will strive to deliver solutions that

align with your operational demands.